tcb.gr - Main Component

Energy Efficiency & Process Optimization

Bunker Control & Fuel Consumption Performance Management

High Accuracy Bunker Control & Fuel Consumption Performance management to manage cheat and defraud of fuel quantity during bunker operations and improve the performance of the ship operation.

Blend Property Control

Oil blending is the final step in the process of converting crude oil into finished products such as gasoline, gas oil and fuel oil. Optimization of the blending process can have a significant impact on quality control, inventory control, throughput of the entire process, and product processing costs. Blend property control improves the performance of the blending process thereby reducing inventory and property fluctuation and minimizes the component cost.

The blending solutions will minimize losses, give away and reduce the need re-blending or correction.

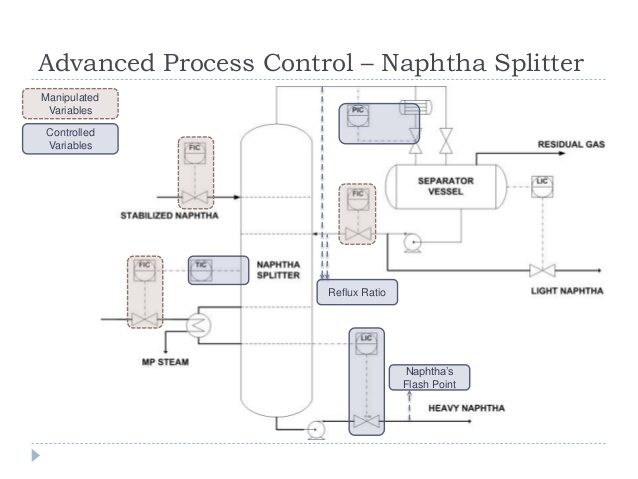

Advance Process Control

An Advance Process Control (APC) solution brings benefits to the operation of a process unit or entire plant, reducing the cost of operation and increasing the yield.

The deployment of a multi-variable controller along with the expertize to perform the development and commissioning, will stabilize the process and improve productivity.

Energy Efficiency Improvements

The operation of an energy system will improve the energy efficiency of a plant at a relative minimum cost.

The system implies:

- Implementation of a real time energy optimizer

- Model of the plant, i.e. in case of a petrochemical complex it accounts for the steam, fuels, electricity and water networks as well as all the indices that are directly related to the energy production cost

The implementation and deployment of such system results in:

- The clear definition of the various utilities systems and their interaction, their variables and constraints

- The tools to act in advance on optimal operation configuration

- Improve efficiency, reducing cost